Uncompromising Stiffness

UCI Approved

EXAR Pro series wheelsets have passed UCI impact tests. After applying an energy of 40 J on the bare carbon rim, the deviation complies with UCI standard.

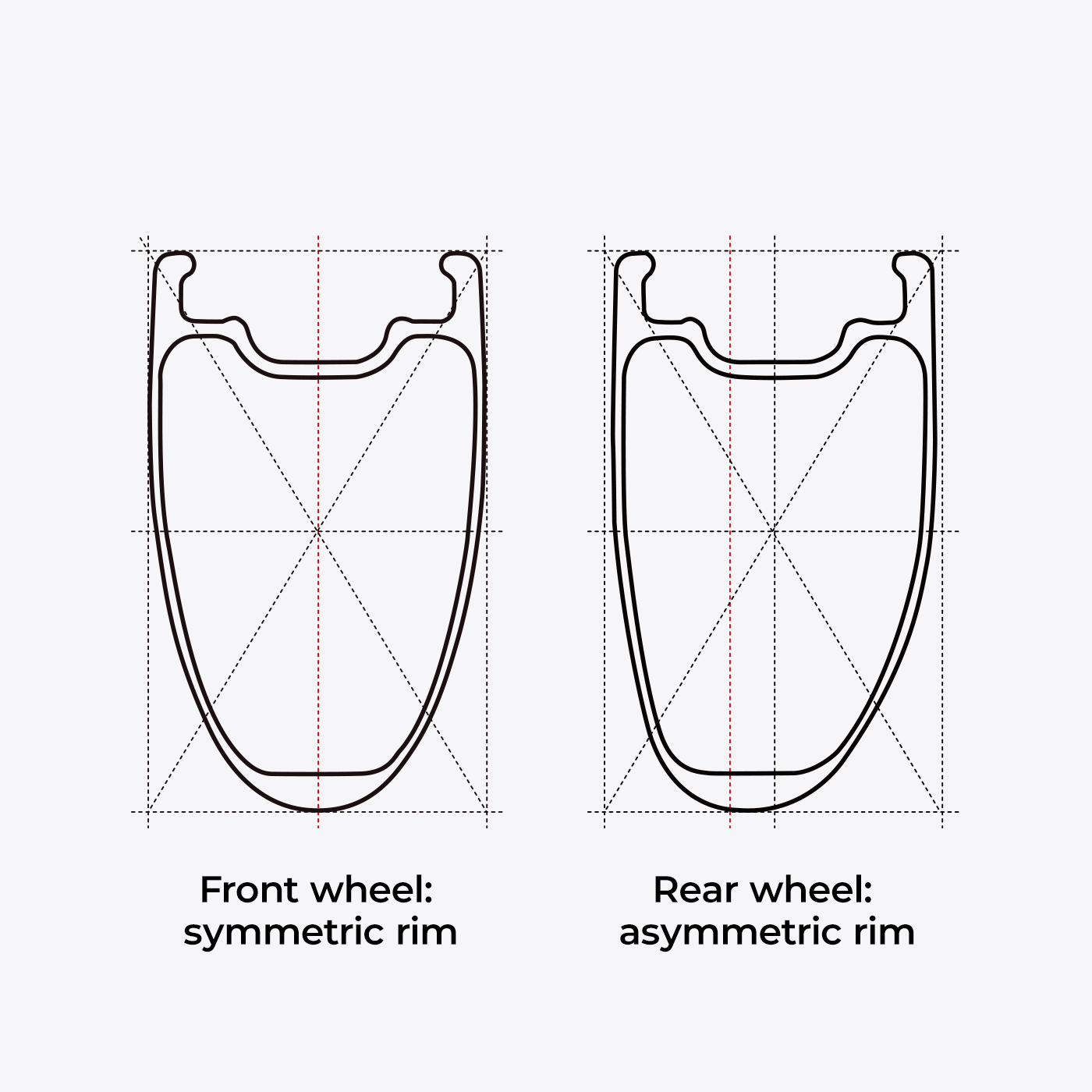

Unique Design of Rim

To improve the wheelset stability, stiffness and crosswind resistance of different frame heights, targeted wheel rim designs were made.

For the 45mm deep rim brake rear wheel, an asymmetric rim design is adopted to balance the rear wheel spoken tension.

For the 58mm deep rim brake rear wheel, a symmetric structure is adopted to prevent deflection due to uneven airflow.

For disc brake wheels, symmetric structure is adopted and the flange width is optimized so that the spoke tension on both sides are close to the same.

The cross-sections of Pro series wheelsets are redesigned for greater stability and rigidity.

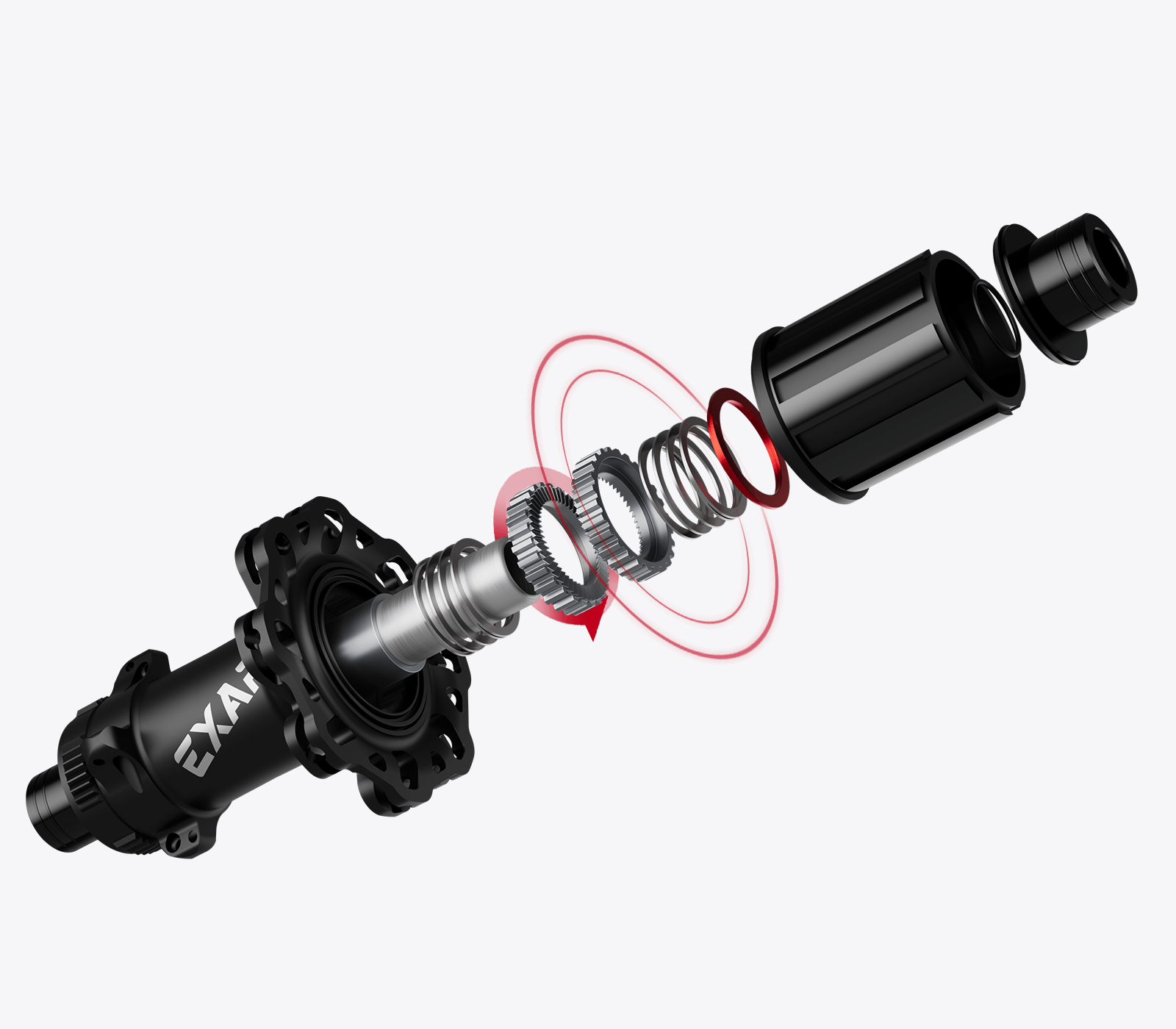

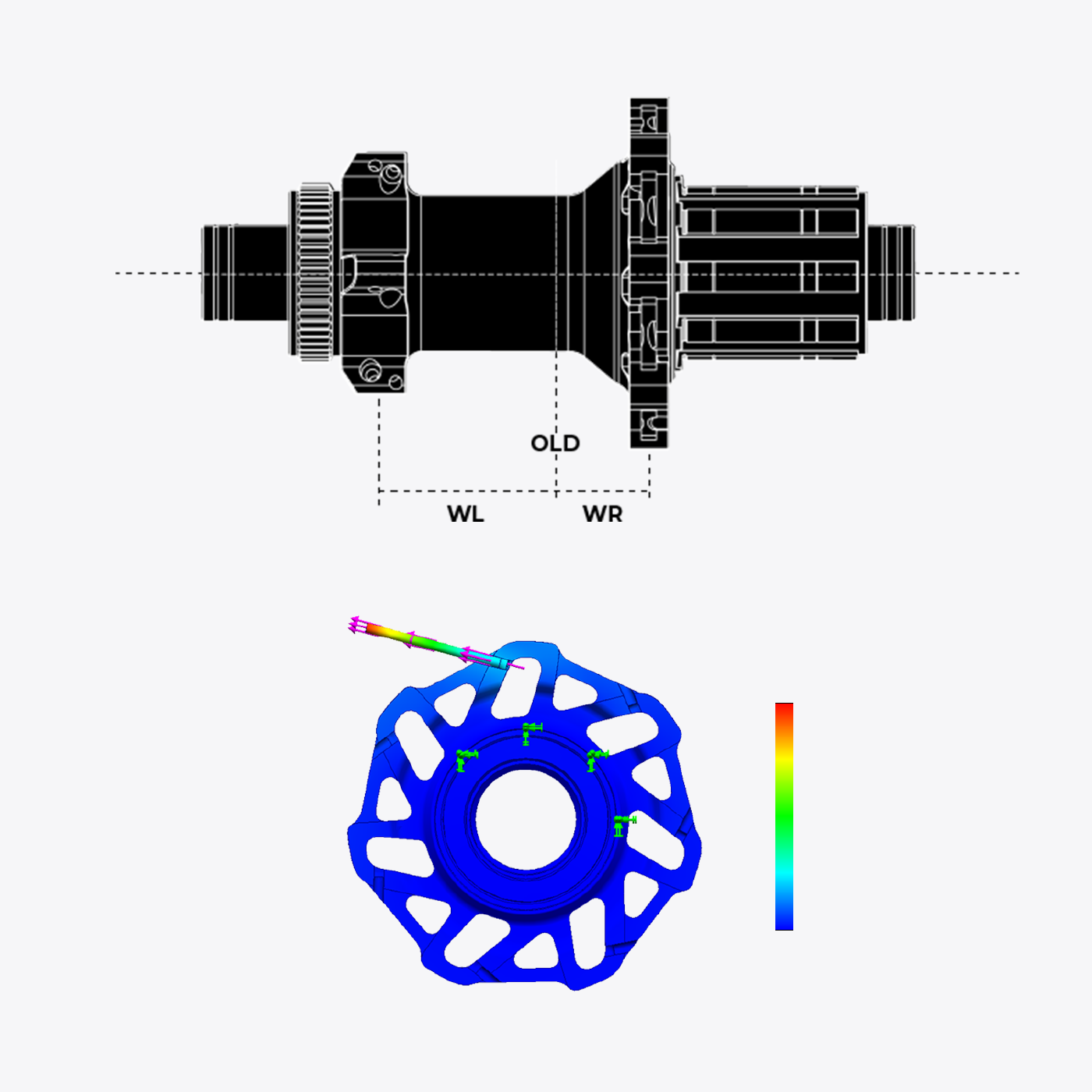

Elaborate Hub Structure

The rear-wheel hub WR size is increased to ensure the spoke tension on the driving side is consistent with that on the non-driving side, hence to deliver outstanding lateral stiffness.

Adopting FEA technology and conducting several tests to identify the maximum force on the hub, to get a light and sturdy hub.

To obtain a better balance lateral stiffness, driving stiffness and braking effect, the front and rear spokes of the disc brake variants have applied a 2:1 balanced lacing pattern, and the hub geometry has been adjusted accordingly.

The rear-wheel drive side flange diameter is increased and the spoke direction is aligned with the torque direction and the wheelset driving efficiency is improved.

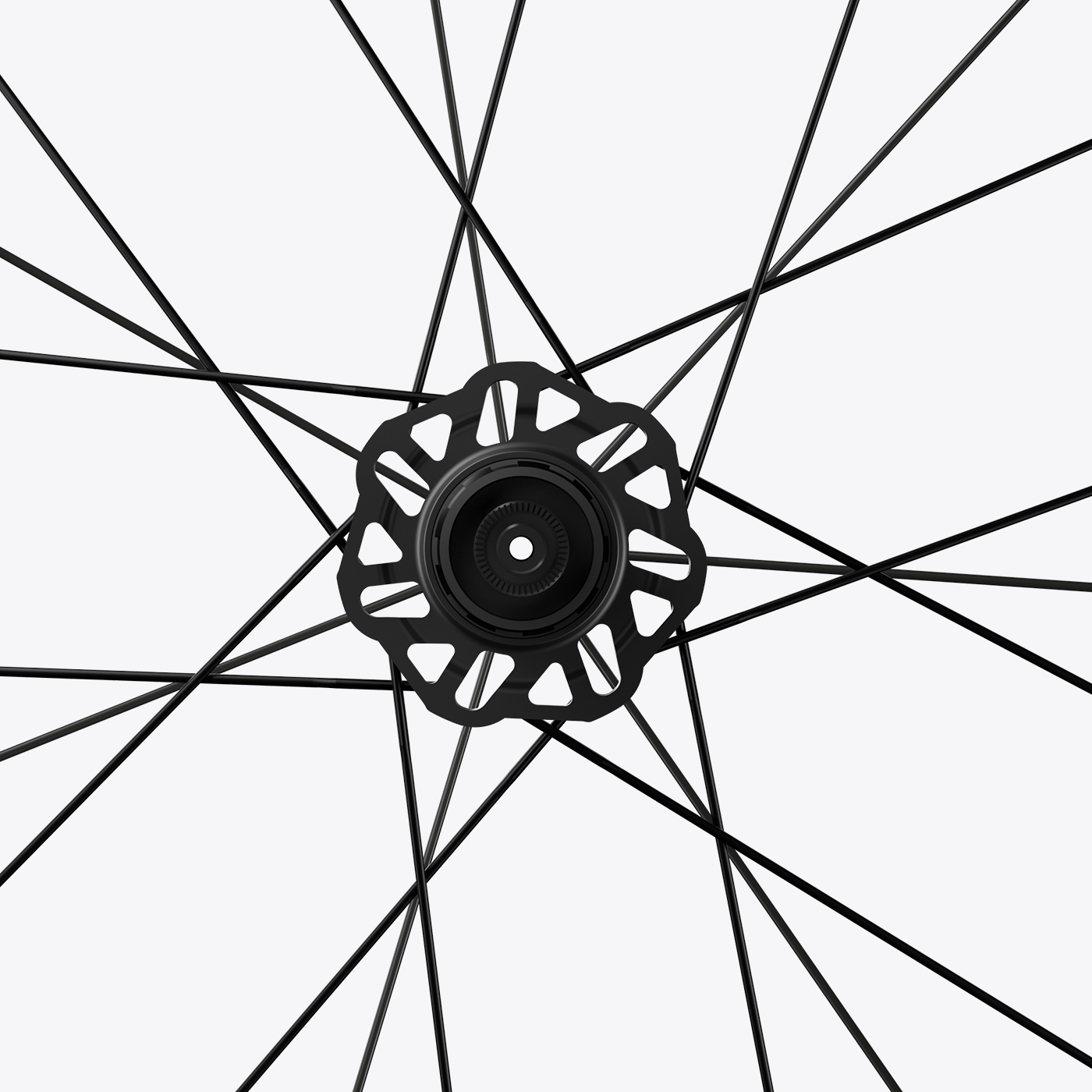

Balanced Design of Spoke Tension

For the rear wheel of the rim brake variant, and both front and rear wheels of the the disc brake variant, the 2:1 balanced lacing pattern is applied to reasonably distribute spoke tension and enhance the pedaling force.

With a standard design of highly stiff spokes, the spoke tension of all models of rear-wheel drive side is 120kgf ±10%, with vigorous and powerful treading.